Unique Wooden Candle Holder Designs for Every Room in Your Home

Candlelight has a magical way of transforming a space, adding warmth, ambiance, and a touch of serenity. And what better way to showcase your flickering flames than with a beautiful and unique wooden candle holder? Wood, with its natural beauty and versatility, offers endless possibilities for creating eye-catching and functional designs. Whether you're seeking rustic charm, modern elegance, or something in between, wooden candle holders can elevate the décor of every room in your home.

Embracing Rustic Charm

For a cozy and inviting atmosphere, rustic wooden candle holders are a perfect choice. Imagine a chunky, weathered log transformed into a candle holder with a simple, yet elegant design. These holders often feature natural bark accents or knots, showcasing the raw beauty of the wood. To add a touch of warmth, consider holders with a distressed finish or a light stain that highlights the wood's grain. These rustic pieces are perfect for living rooms, bedrooms, or even your porch, bringing a touch of nature indoors.

Creative Rustic Ideas

- Reclaimed wood candle holders: Give old wood a new life by crafting a unique candle holder. Look for weathered pieces like old barn wood or salvaged pallets.

- Tree stump candle holders: Transform a slice of a tree trunk into a stunning centerpiece. You can leave the bark intact or carve out a simple design.

- Driftwood candle holders: Embrace the beachy vibe with driftwood candle holders. These naturally sculpted pieces offer a unique and organic aesthetic.

Modern Elegance with Wood

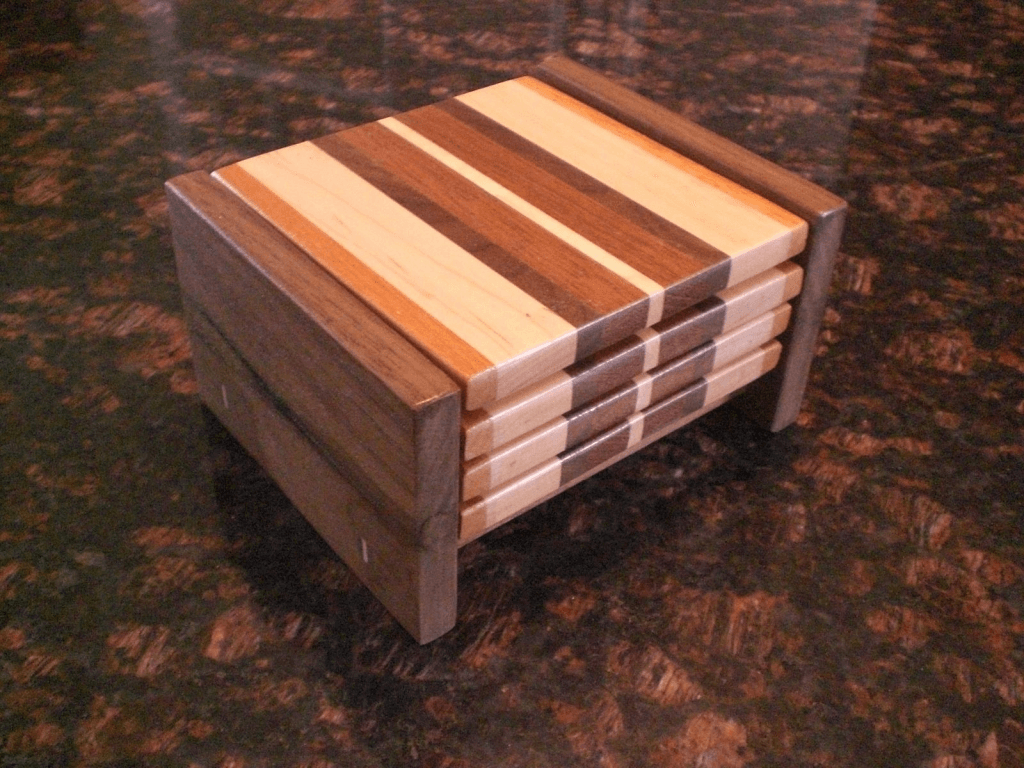

Wood can be just as sleek and contemporary as any other material. Modern wooden candle holders often feature clean lines, geometric shapes, and minimalist designs. Choose holders with a smooth, polished finish, perhaps in a dark wood like walnut or ebony. These minimalist pieces add a sophisticated touch to modern living spaces, dining rooms, or even home offices. They can be used to create a calming and focused atmosphere, making them perfect for meditation or relaxation.

Modern Wooden Candle Holder Ideas

- Geometric candle holders: Embrace the modern aesthetic with holders that feature geometric shapes like triangles, squares, or cylinders.

- Metal and wood combinations: Combine the warmth of wood with the sleekness of metal for a truly modern look. Look for holders with brass accents, or those where wood frames a metal base.

- Scandinavian-inspired designs: Embrace the simplicity and functionality of Scandinavian design with holders featuring clean lines and natural wood finishes.

Beyond the Ordinary: Unique Wooden Candle Holder Designs

For those seeking truly one-of-a-kind designs, the possibilities are endless. Artisans and woodworkers are pushing boundaries, creating intricate, handcrafted wooden candle holders that are both functional and artistic. From intricate carvings and laser-cut designs to holders that incorporate natural elements like shells or stones, these pieces are statement makers. Consider a wooden candle holder that resembles a miniature sculpture or one that incorporates sustainable materials and eco-friendly practices.

Unique Wooden Candle Holder Inspiration

- Sculptural designs: Seek out holders that have been crafted into unique shapes, mimicking natural forms or abstract ideas.

- Intricate carving: Look for holders that showcase intricate carvings, perhaps featuring floral motifs, animal designs, or geometric patterns.

- Personalized designs: Commission a custom-made wooden candle holder that incorporates a special message, date, or personal symbol.

Wooden candle holders are more than just functional accessories; they are pieces of art that bring warmth, light, and personality to your home. Whether you choose a rustic, modern, or uniquely crafted design, let the natural beauty of wood illuminate your space and inspire a sense of tranquility and comfort.